|

The Tork-Mate 890 series extended life actuators are ideal for the operation of 90° turn devices such as butterfly valves, ball valves, plug valves, damper valves and other devices. Tork-Mate pneumatic actuators have features that are unique, providing many benefits to the user looking for worry-free service.

TMHC 2324 TMHC 2324

A proprietary two-step hardcoat process that offers superior protecion on interior and exterior housing surfaces. TMHC 2324 also ensures maximum life from the piston seals, piston bearings and heel bearings.

NAMUR Mounting NAMUR Mounting

Tork-Mate 890 series actuators meet the latest NAMUR standards, allowing direct or close coupling of NAMUR designed accessories. The pinion interface features a positive, international standard drive for positioners, switches and other accessories. The solenoid interface allows direct acceptance of any NAMUR designed control valves.

Modular Modular

Easily removable end caps and modular spring packs simplify the conversion from double-acting to spring-return configurations.

|

|

Travel Adjustment Travel Adjustment

The Tork-Mate 890 series actuators feature pinion travel stops that allow a full +/-10° of valve travel adjustment. As an option, extended stroke adjustment screws can be added for inexpensive throttling applications.

Extended Cycle Life Extended Cycle Life

Special piston seals provide greatly extended life compared to standard O-ring actuators. All other bearings, seals and components have been engineered to provide superior and extended service lives.

Blow-out Proof Pinion Gear Blow-out Proof Pinion Gear

In addition to the stainless steel pinion retaining ring, the Tork-Mate 890 series actuators feature a unique internal safety bar.

Operating Ranges Operating Ranges

Tork-Mate 890 series double-acting actuators produce guaranteed minimum torque outputs up to 17,466 inch pounds (1973 Nm).

Custom Options Custom Options

These include Viton® seals, high temperature trim up to 250° F (121° C), special finishes, stainless steel pinions, special mounting configurations and special coupling configurations.

Imperial or Metric Mounting Imperial or Metric Mounting

|

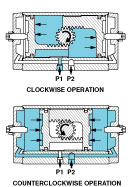

Double-Acting

For clockwise operation, Port 2 (P2) is open to atmosphere and air pressure is directed to Port 1 (P1). As the pistons move apart, the pinion rotates clockwise. The linear movement of the pistons is converted to rotary  motion by the piston racks and the output pinion gear. motion by the piston racks and the output pinion gear.

For counter-clockwise operation, Port 1 is open to atmosphere and air pressure is directed to Port 2.

The pressure differential moves the pistons together, rotating the pinion counterclockwise.

|

|

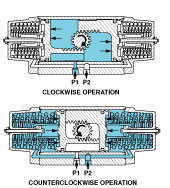

Spring Return

For clockwise operation, Port 2 is open to atmosphere and air pressure is directed to Port 1. The air pressure compresses the springs and moves the pistons outward. As the pistons move apart, the pinion rotates clockwise.  The linear movement of the pistons is converted to rotary motion by the piston racks and the output pinion gear. The linear movement of the pistons is converted to rotary motion by the piston racks and the output pinion gear.

For counter-clockwise operation, Port 1 is open to atmosphere and air pressure is directed to Port 2. High pressure and/or spring force moves the pistons inward, rotating the pinion counterclockwise.

|